Credentials & Case Study

How Clean Oil Cuts Emissions and Boosts Engine Life: A Case Study

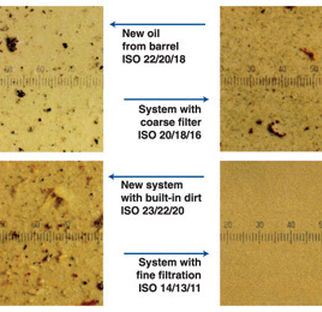

A national food service provider saw remarkable improvements in the performance of their trucks and refrigeration units after installing our ultra-fine fluid filters. Prior to installation, oil analysis revealed an excessive amount of contaminants, making it impossible to attain the required ISO code. However, with our filters in place, contaminants were progressively filtered from 10 down to 1 micron, resulting in oil that was cleaner after a few thousand miles than their new oil used during oil changes.

Most regular full flow filters can only clean oil at about 15-40 microns, which leaves a significant amount of contaminants between 3-7 microns. While this rate of wear has been deemed acceptable by manufacturers, studies conducted by General Motors, Caterpillar, and others show that engine life can be significantly extended by keeping oil clean.

Our SET ultra-fine by-pass oil filter was able to achieve an ISO cleanliness code of 19/16/9 after just two months of daily driving, a stark contrast to the black and opaque oil seen in the "before" picture. The particle count of contaminants greater than 4 microns dropped from 2.7 million to 261,000, and the oil was even cleaner than their new oil which achieved an ISO cleanliness code of 21/18/12.

According to a study conducted by General Motors, the engine life can be extended up to 8 times when oil is fine filtered to 5 microns. Now, imagine the extended engine life you can achieve by filtering down to 1 micron.

Similar to the truck, the refrigerated trailer also experienced a noticeable improvement in oil quality after the installation of the SET 2500 ultra-fine bypass filter. Before the installation, the oil was extremely dirty and did not meet the ISO code standards. However, the next oil analysis conducted after a month of daily use achieved an ISO code of 19/17/11, indicating a significant improvement in oil cleanliness. As with the truck, the filtered oil was even cleaner than the new oil poured into it.

To demonstrate the improvement in oil quality, the lead mechanic pulled out the dip-stick from the diesel engine of the refrigeration unit. At first, he thought there was no oil on it, but then realized that the oil was clear and clean. Check out the picture to the bottom right for reference.

Preventing Equipment Damage with Proactive Oil and Filtration Analysis: A Case Study

Aiming to decrease emissions, prolong equipment life, and cut down on maintenance and fuel expenses, one of the world's largest mining companies took a more assertive approach towards fluid filtration and oil analysis. During this process, the team detected a gradual increase in copper and iron particle counts. Despite being below the manufacturer's alarm limits, the team decided to investigate further and discovered a main bolt fracture that was causing undue strain on the main and rod bearings. Thanks to their swift action, a catastrophic failure was averted and the repairs were covered under the manufacturer's warranty.